When it comes to maximizing effectiveness and performance of the engine, fuel quality is a key factor. In time diesel fuel could become polluted by impurities such as sediment, water and microbial growth that can affect the operation of engines and result in costly repairs. Polishing your fuel is a fantastic method to make sure that your engines run efficiently and fight fuel contamination.

Fuel polishing, also known as diesel fuel polishing is a process of eliminating impurities and contaminants from diesel fuel. It is a service that is provided by experts who use advanced techniques and equipment to restore fuel to its optimal condition. Polishing the fuel improves engine performance reduces maintenance costs, and prolongs the lifespan of equipment through the removal of harmful substances and improving the quality of fuel.

Numerous polishing services for fuel are available to cater to the various needs of industries that depend on diesel fuel. They employ highly skilled technicians with expertise in fuel systems and are aware of the complexity of contamination in fuel. They are able to identify fuel problems with their specially designed equipment and in-depth understanding.

The purpose of polishing fuel is to eliminate water as well as sediment, sludge and microbial contaminants from diesel fuel. Because of leakage and condensation in fuel tanks there is a tendency for water to build up creating corrosion and deterioration of the fuel. It also encourages the development of fungi, bacteria, as well as other microorganisms. Sludge and sediment may result from impurities in the fuel, or gradual degradation of fuel components. These substances can block filters and injectors as as other essential components. This could lead to reduced engine performance or even a failure.

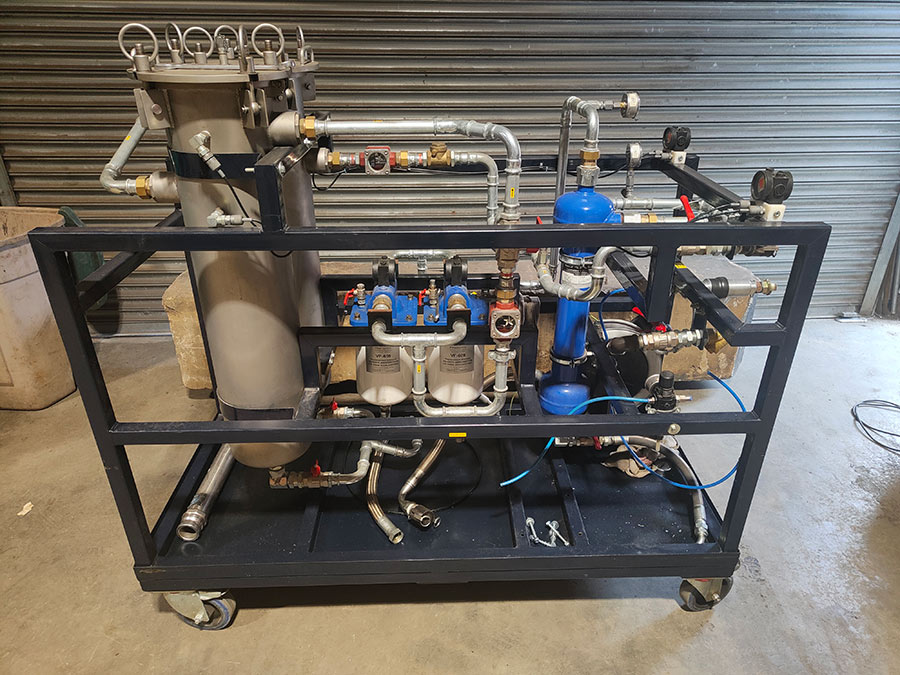

Diesel fuel polishing typically involves a multi-step process. It begins with sampling of fuel and analysis to assess the level of contamination and determine the appropriate plan of action. Once the analysis has been completed technicians utilize filtration systems to remove contaminants and impurities from the fuel. They use various filters and media to effectively remove fuel-borne contaminants.

Regular fuel polishing offers several key benefits. It improves the fuel quality and ensures that engines get clean, consistent fuel to allow for optimal combustion. Performance and efficiency of fuel are improved, resulting in cost savings and lower emissions. In addition, it reduces the risk of engine breakdowns and damage due to contaminated fuel. It assists in maintaining the durability and integrity of engine parts by eliminating harmful substances.

Regular diesel fuel polishing (also referred to as polishing using diesel) offers many benefits in keeping the quality of fuel. In the first place, it assists to get rid of contaminants like water, sediments, as well as microorganisms that could negatively affect the performance of engines. The quality of the fuel is improved significantly through the removal of these impurities by the diesel polishing process. This is a result of improving the efficiency of combustion, resulting in an increase in fuel economy and decreased emissions. Secondly, regular diesel polishing helps prevent the clogging of fuel filters, injectors, and other vital components, reducing the possibility of engine damage and expensive repairs. The process of polishing fuel is crucial for the long-term health of the fuel storage system and reduces the accumulations of sludge, corrosion, and other contaminants. Regularly polishing the diesel fuel can have a number of advantages, including better efficiency of the engine, lower costs and increased reliability.

Moreover, fuel polishing services can be tailored to meet the particular requirements of various industries and applications. The process of polishing fuel can be applied to a variety of applications, ranging from boats and backup engines to construction machinery and transportation fleets. It is essential for businesses that depend on a an uninterrupted and stable power supply, and businesses operating in remote and extreme environments where fuel quality can be a problem.

In the end, fuel polishing is an important process that assures the purity and quality of diesel fuel. It boosts engine performance decreases maintenance costs and prolongs the life of equipment through the removal of contamination and impurities. The investment in professional fuel polishing services allows industries to safeguard their operations, enhance performance, and mitigate the dangers associated with fuel contamination. So, whether you are managing several vehicles or operate critical power systems take a look at the benefits of polishing fuel to unlock the full potential of diesel fuel, and propel your business ahead.